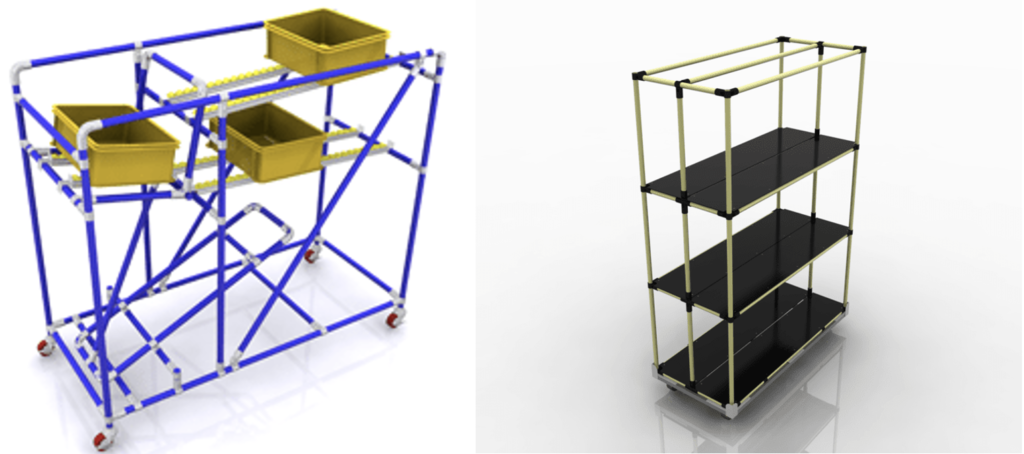

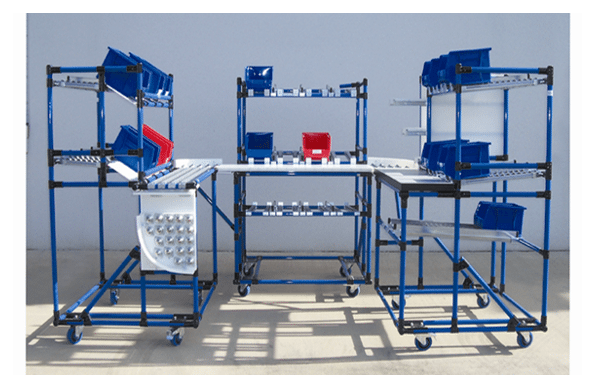

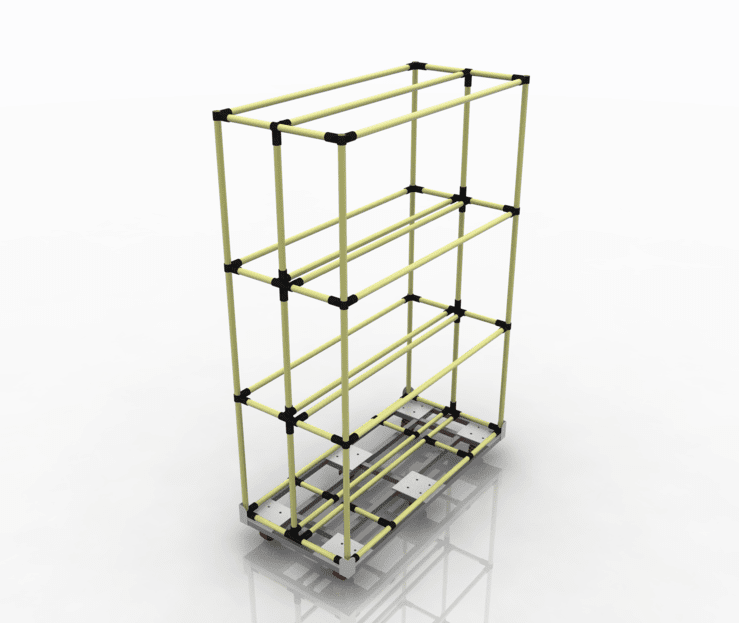

Flow racks vs. storage racks

Having the right type of equipment is essential for having a safe, functional, and productive work environment. The rack is one of four kinds of equipment that contribute to successful material flow in a workplace, along with packaging, work stations, and carts. The category of racks includes two different types, which are called flow racks…

Read MoreWhat is lean consulting?

You may already be familiar with the term “Lean,” but do you know how it is implemented? Sometimes, it takes an expert to tell you how to get started, which is just what a lean consultant will do. A consultant is a professional who is familiar with Lean’s principles and knows how they should be…

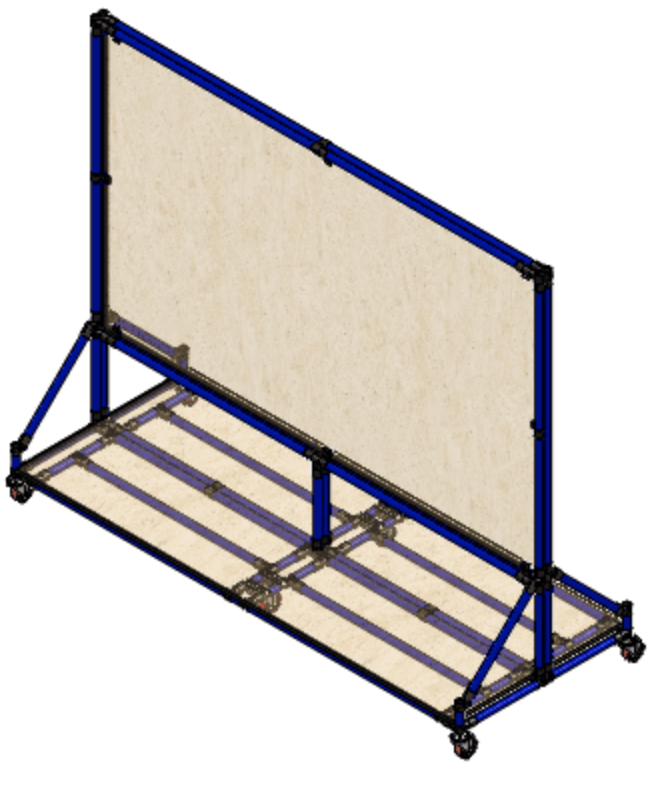

Read MoreProduct spotlight: Information boards

In the business world, companies are always looking to improve. One way that they strive to improve is through information dissemination. You may be aware that there are different methods available for relaying information, and different avenues are more appealing to consumers than others. One popular way to provide information to customers is through visual…

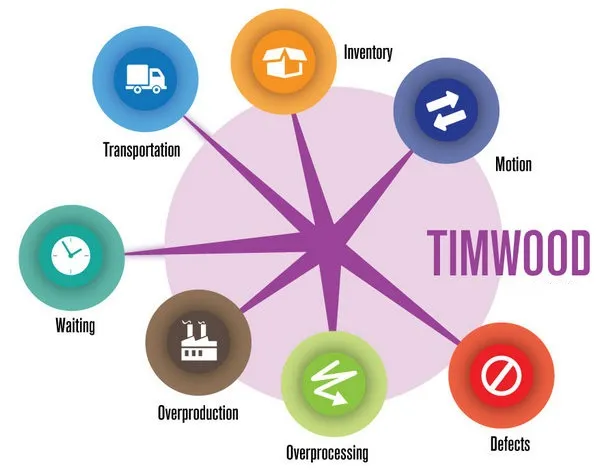

Read MoreWhat is Mura, Muri and Muda?

You may have heard about the concept of lean manufacturing, but do you really know what it’s all about? If not, no worries – the helpful and knowledgeable staff at C Tek will happily explain. Along with learning all about lean manufacturing, the C Tek staff can tell you about the various aspects of lean…

Read MoreIs Apple lean?

Lean companies are pegged as some of the most progressive and admirable in the business industry. Many world-renowned companies have adopted or even championed lean practices and ideology, including Toyota. One of the world’s most iconic brands is Apple. The company is certainly a leader in software and computer technology. However, many are still left…

Read MoreHow can apparel manufacturers implement lean

Lean is a valuable tool that can benefit many industries. While lean’s benefits are widely recognized in the manufacturing industry and related sectors, one industry where you may not think to find it is the apparel industry. However, the apparel industry benefits tremendously by implementing lean’s principles into its practices. If you are in the…

Read More5 skill sets developed in lean six sigma training

These days, the more skills you have as an employee, the more valuable you are to your employer and to future employers if you ever decide to switch jobs. One of the most coveted skills that you can get is Six Sigma, which encompasses a variety of principles and methods that are valuable to businesses…

Read MoreEfficient vs. responsive supply chains

If you are looking to make improvements in your company’s operations, C Tek has a key suggestion, which is to take a look at the supply chain that you are using and make any changes if necessary. Using the right supply chain is critical for efficient business operations. In addition to helping your company function…

Read More5 lean manufacturing resources

If you are familiar with lean manufacturing, you may be glad to know that there are a number of resources available to improve efficiency, production, and ultimately bottom line. Lean’s ultimate goal is to find a simpler, faster, and ideally more cost-effective way to get things done. You will, in turn, need put in less…

Read More5 examples of lean manufacturing

Lean manufacturing has many tools and techniques that are valuable for businesses. Regardless of whether you are just starting to implement lean practices into your workplace environment or you want to improve existing processes, C Tek will share some good examples of companies that have successfully integrated lean’s techniques into their own practices. Collectively, these…

Read MoreHow does lean manufacturing work for a batch process?

Lean manufacturing is a popular practice that can benefit many different businesses. One industry that benefits from implementing lean is batch production, or batch processing. Many customers mistakenly think that lean only applies to large-scale production companies rather than smaller niche markets. However, as the experts at C Tek will explain, lean manufacturing also has…

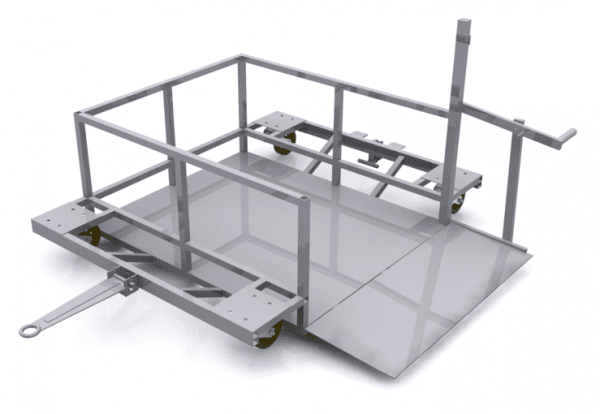

Read More3 ways work stations can benefit your company

It might not sound like a big deal, but having a proper workstation setup can provide many benefits for a business. With the right workstation, employees will benefit from a physically healthier workspace and a more productive workspace. Taking the time to show that you care about your employees’ health and wellbeing also makes them…

Read More