Posts Tagged ‘5S’

3 Tools Everyone in the Lean Industry Should Be Using in 2020

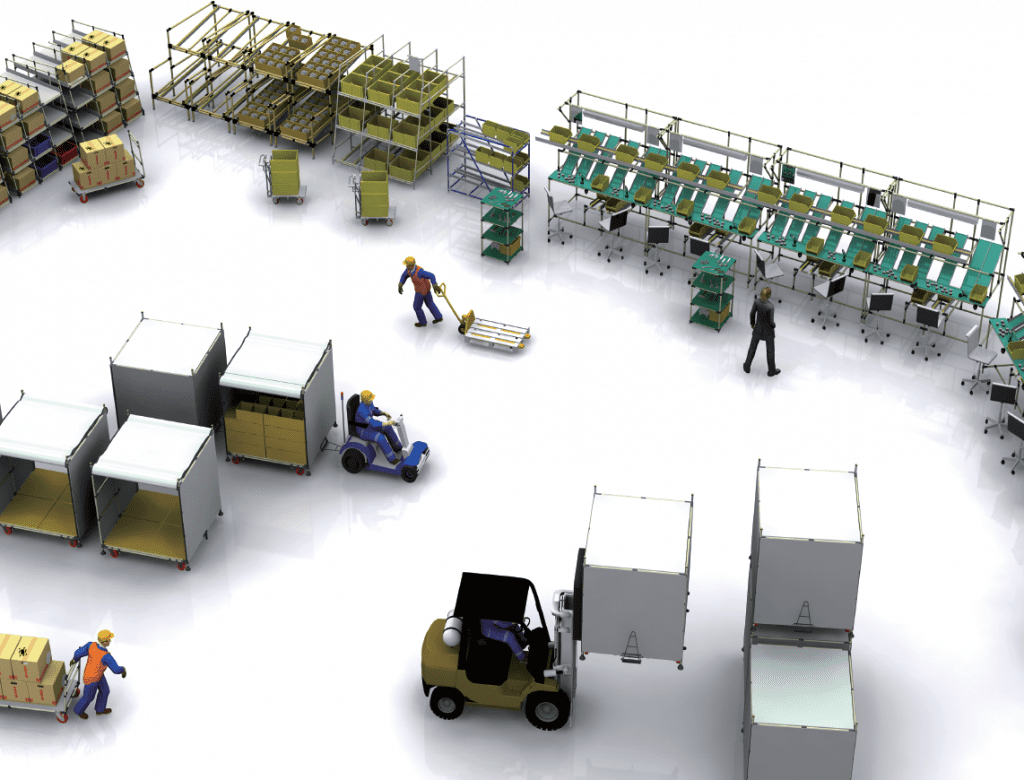

Lean Solutions Tools Businesses of all sizes, within every industry, are always looking for innovative ways in which they can maximize productivity, reduce cost, and make their operation as efficient as possible; lean solutions will do just that. Practicing lean solutions enhance the productivity and safety of workplaces, with a particular focus on the manufacturing…

Read MoreYour 2020 Guide to Lean Solutions

In this ultra-competitive marketplace, every business is looking for the “edge.” Regardless of your company’s size, industry, or geography, implementing a lean mentality and process design will help your team excel against your competition. It’s a mentality, culture, and way of business that helps you get to the next level. Businesses that implement these solutions often experience…

Read More6 Reasons to Invest in Lean Manufacturing

Introducing automation in your manufacturing process can be a big breakthrough for your organization. Several organizations begin to put into consideration methods by which they can improve their pricing, maximize profits, cut expenditures, and grow customers. Today’s customers are pertinent on getting goods and services at improved costs, with better quality and prompt delivery. Obtaining…

Read More7 Myths About Lean Solutions

Lean solutions can hold different meaning to different teams and difference companies. Although the implementations, productivity, and process changes may differ from plant to plant, the basic tenets remain the same. So do the myths that continue to exist due to inappropriate education at all employee levels. What Lean Achieves The goals of this philosophy,…

Read More4 Easy Ways To Bring Lean To Your Work Floor

You may conceive of lean as a philosophy and methodology for large corporations, but it’s easier to implement and just as useful for small to mid-sized businesses. Regardless of your product, a philosophy of continuous improvement lets you streamline material handling, better organize production, and standardize procedures. Getting started with the philosophy that revved up…

Read MoreWhy Some Teams Miss The Mark When Going Lean

Lean management and manufacturing processes can help an organization improve its productivity and revenue by 40 to 60 percent in a short time. Improperly implemented, it can hurt the firm. You can ensure proper implementation by recognizing the mistakes others have made that didn’t lead to success and planning around those. Key Terms In any…

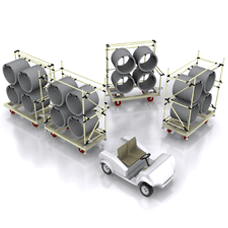

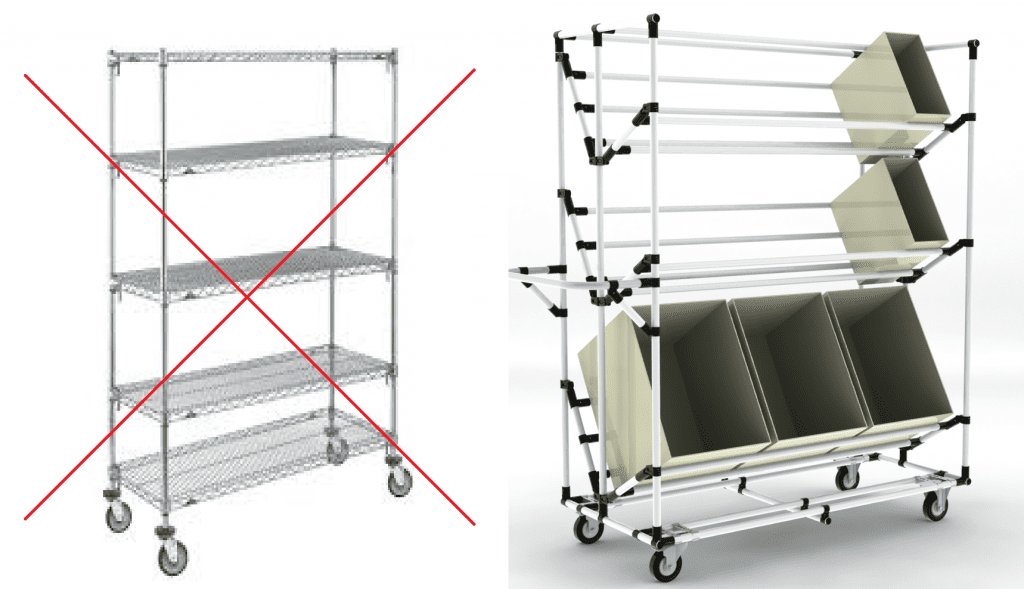

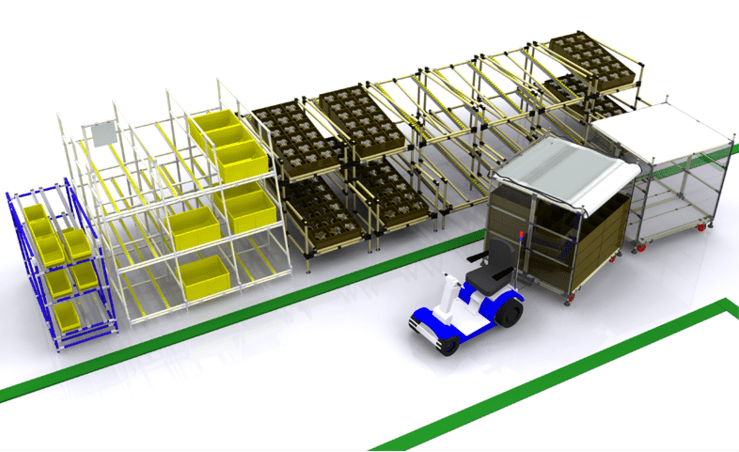

Read More6 Custom Carts to Increase Floor Productivity

The cart, utilized on almost all work floors, is one of the keys to enhanced floor productivity. While many still utilized multiple uniform structures, carts provide optimum benefit through customization, providing invaluable benefits. Benefits of Carts Using carts to move products achieves five important items in one device: 1. Ergonomics 2. Safety 3. Space Savings…

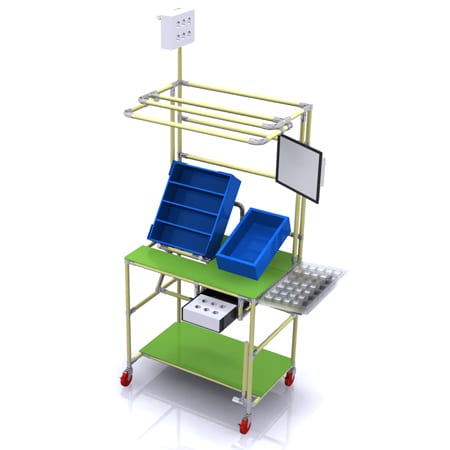

Read MoreWhat are the Best Workstations for your Work Floor?

The ideal workstations for your manufacturing floor serve multiple purposes. They must also serve the company’s needs for quick, error-free assembly. Additionally, employee safety must be considered, protecting individuals from cumulative trauma disorders like carpal tunnel, and joint pain. While this customized need may sound like an expense that violates the tenets of lean manufacturing,…

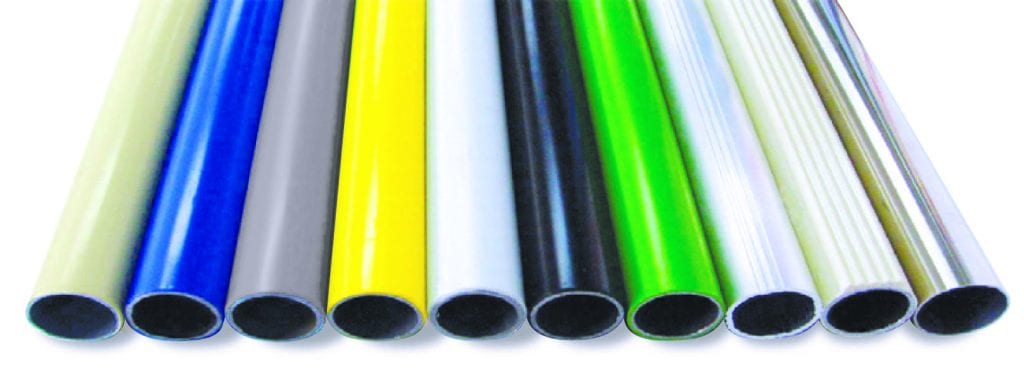

Read More101 Essentials on Building with Pipe and Connector

You have probably seen pipe and connector structures used in different manufacturing environments. You may have even built projects with the materials around the house. These versatile construction components, however, can be used beyond simple projects, and help you improve your company’s production line. Any lean manufacturing or management program relies upon making instant changes…

Read MoreEverything You Need To Know About Lean Manufacturing

Lean manufacturing combines the leading thought and line processes with the most successful business philosophies. While lean benefits from worldwide learning examples, this process of waste reduction and efficiency building usually focuses on the Japanese management philosophy of kaizen and the 1980s Toyota line processes. Not Just Manufacturing While most commonly associated with manufacturing, these…

Read More7 Things To Avoid When Practicing Lean Solutions

Sometimes, following directions proves the easiest way to do something. Of course, as important as the “dos” are to any undertaking, so are the “don’ts.” This proves true when practicing lean solutions. Though the practice of lean solutions has developed in the past 25 years, their core tenet remains the same: simultaneously maximize customer value…

Read More4 Benefits of an On-Site Visit

Getting Ready for Company Implementing “lean” is a journey. Many employees will be unsure how this process will impact their activities — open and candid conversations will uncover opportunities on how lean can improve their efficiency and job satisfaction. We find many of our partners prefer us to assist in this “discovery phase”. During a…

Read More