Send us a quote in under 5 steps

We’ve revamped our product catalog page to make it easier for C Tek Lean Solutions’ customers to get quotes for the items they need. Please click here to explore the changes. From there, you can browse our entire catalog or check the boxes on the left of the page to see only the brands and categories…

Read MoreThe Benefits and Drawbacks of Powder Coating

Powder coating is a process in which a powder is sprayed, in a sealed spray booth, over a typically metal product or item. The product is then heated to a specific overall temperature of the item for the powder to melt which creates a solid, even, thicker coating of a protective film. There are also…

Read MoreIdentifying Waste in Your Organization

When it comes to lean manufacturing there are eight ways that your company can experience waste that affects the bottom line. Many of these waste aspects can be fixed and C Tek Solutions is your answer to identifying and then answering waste problems in your production lines. We have the experience, knowledge, and talent to…

Read MoreAdapting Lean Manufacturing Techniques for High-Mix Assembly Operations

Why High-Mix Assembly Is Imperative In today’s manufacturing world, there are two routes a business can take. The first is the high volume but low-mix assembly approach in which a business specializes in just a few products and focuses on maximizing the production of just those products. The other is the high-mix assembly approach in…

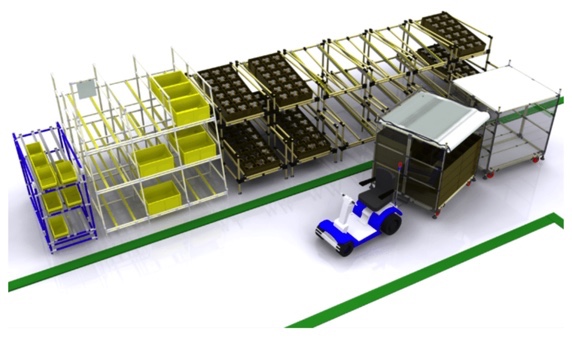

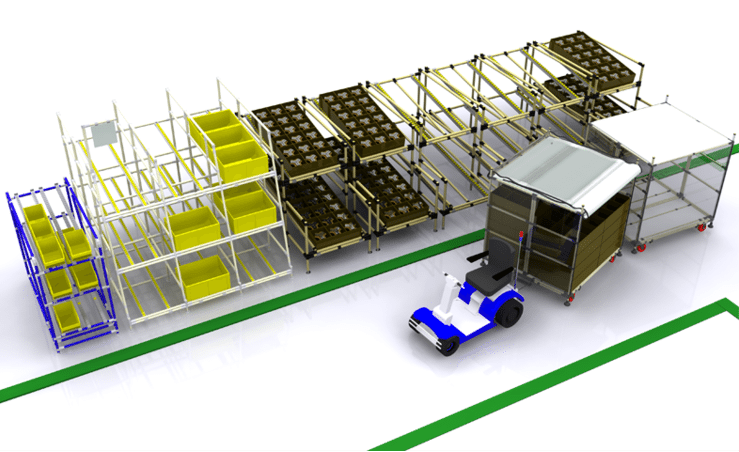

Read MoreReduction of Floor Usage with Lean

“I used to always work in, like, warehouses, because if my boss gave me a rough time, I could just get on a forklift and just, like, drive away from him.” -Bill Burr Many places across the country want to expand their business capacity, yet they do not have the room within their facilities. Furthermore,…

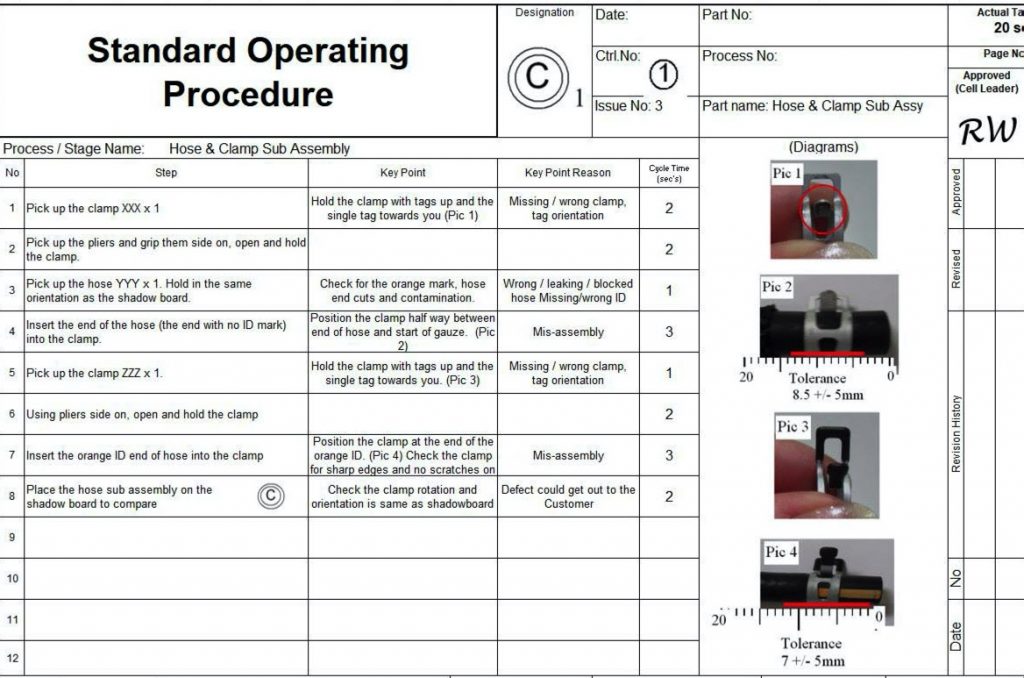

Read MoreStandard Work and Lean

“Standards should not be forced down from above but rather set by the production workers themselves.” -Taiichi Ohno The first time I wrote an SOP, Standard Operating Procedure, it was long-winded. A step by step way to perform the process of each job within a process; too many words and no pictures of the process.…

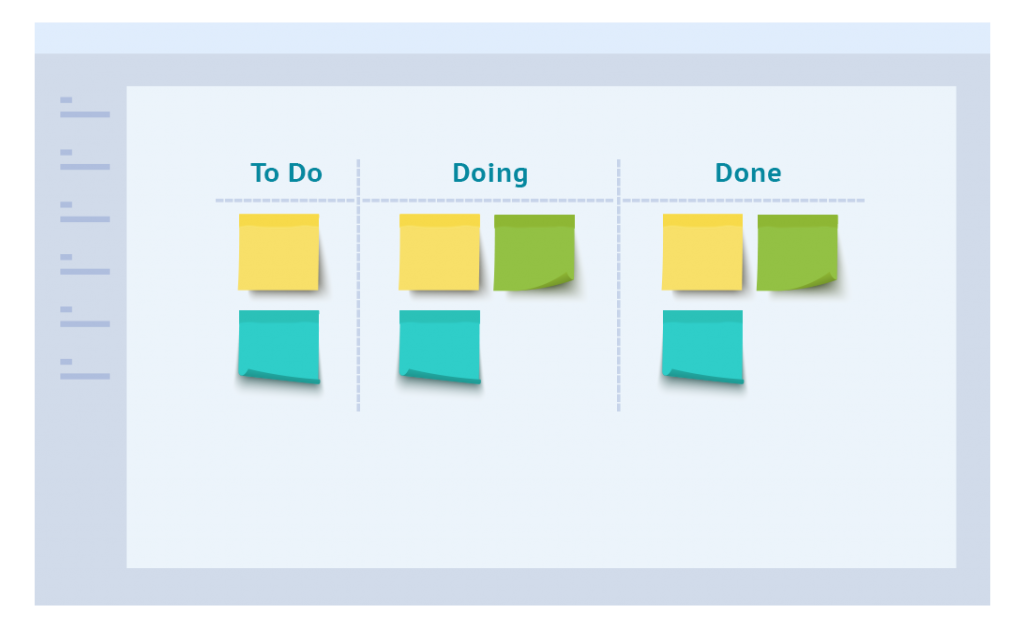

Read MoreCreating Kanban

The ultimate goal of Lean is to have one-piece flow and zero inventory in the system. Though this may never be achieved within the system, this is the pursuit of perfection by those who practice Lean. The purpose of this is to have the ultimate respect for people by giving them the leadership to learn…

Read More4 Competitive Advantages to working with C Tek Lean Solutions

When deciding to utilize modular pipe & joint systems for the first time OR if you are looking for new cost-effective and compatible alternatives to existing suppliers such as Creform, National Integrated Systems (NISAMERICA) or Trilogiq, you may want to consider C Tek’s Competitive Advantages: C Tek Experienced Ownership, Sales & Design Teams: C Tek…

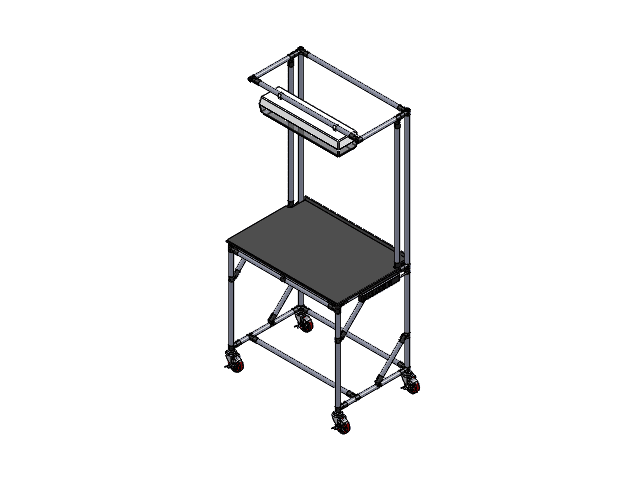

Read MoreDeciding What Cell Design Will Fit Your Departments

Written by Jason Haines Around six months ago I was introduced to C Tek Lean Solutions and their products that provide the ability to build carts, workstations, and many other products to fit your facility and its processes. If only I had known about them back when I worked at an essential oil plant! Instead…

Read MoreWhat Are the Differences between Automation and Autonomation?

Written by Jason Haines Many companies have invested in machines and computer programs that have assisted to automate their processes to grow their businesses. These investments have led them to produce more than ever before and find ways to fulfill the customer demands at a higher pace than they ever imagined. Whether a new machine…

Read MoreWhat is One-Piece Flow?

Written by Jason Haines The ultimate goal of installing Lean Manufacturing into any facility is to have no inventory and create a One-Piece Flow system that will ultimately show respect for all people in an organization. You may never reach any inventory and full One-Piece Flow, but companies will bring a culture of respect for…

Read MoreWhat is the Goal of Lean Continuous Improvement?

Over the year’s organizations have tried to implement Lean into their businesses and failed or stopped moving forward with the program. Most of the time you hear the same old excuses, “we tried that here and it just didn’t stick”, or “we were to busy to ever make the change”. There is a multitude of…

Read More