Posts by Ben Martin

The Importance of reducing cycle time

No matter what industry you work in, having a shorter cycle time has many advantages. Fortunately, it’s fairly easy for manufacturers to manage their cycle time. From increased rates of customer satisfaction to lowering operating costs, shortening the production cycle time also provides many benefits, as C Tek Lean Solutions can explain. What is…

Read MoreThe 5 dimensions of lean implementation explained

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process. Ultimately, their goal is to maximize profit and efficiency while reducing waste. The experts at C Tek Lean Solutions will walk you through the steps…

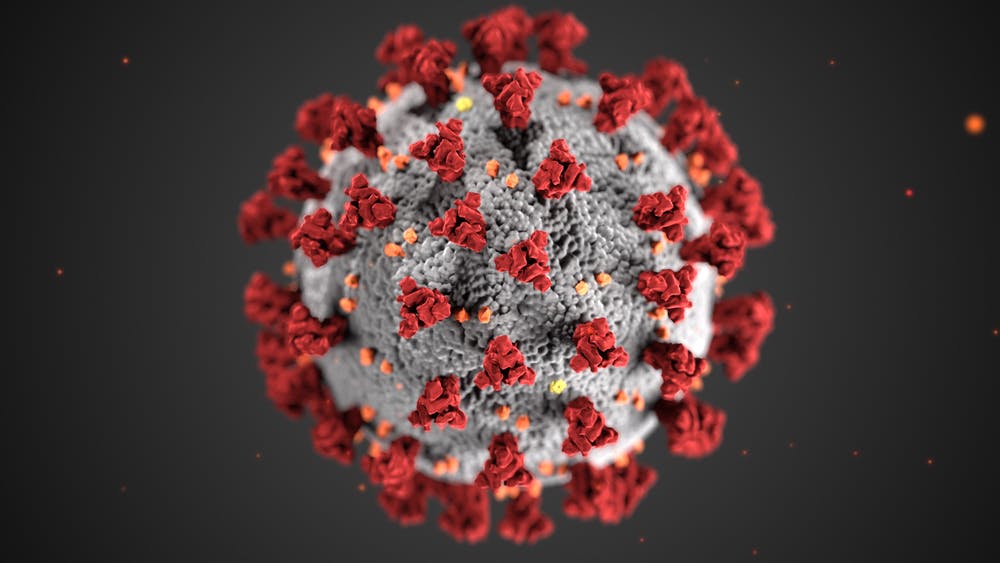

Read MoreHow does lean manufacturing prepare for supply chain issues like Covid-19?

For more than a year, the COVID-19 pandemic has affected just about every aspect of business operations. The global pandemic has also had an impact on the supply chain around the world, which has caused lengthy delays in production and shipment. Items that were previously relatively fast to manufacture and ship, such as bicycles, furniture,…

Read MoreWhat is ISO 9001 and why is it important?

You may have heard of the term “ISO 9001” before, but do you know what it means? If not, the knowledgeable staff at C Tek Lean Solutions will happily fill you in. ISO 9001 is a quality standard developed by the International Organization for Standardization (ISO). It is the largest organization in the world responsible…

Read MoreWhat makes working in a lean manufacturing environment enjoyable?

Making the change to a lean-based work environment has multiple benefits for companies. Along with improving efficiency, minimizing waste, and saving money on operating expenses, leaner manufacturing can also create an enjoyable work environment, as it is designed to maximize efficiency and productivity. It may create a healthier and safer work environment, and it is…

Read More3 Things To Know About Norman Bodek

The concept of lean manufacturing is synonymous with the name “Norman Bodek.” Norman Bodek, known as the “Godfather of Lean,” is a pioneer of lean manufacturing in the United States. He passed away in December 2020 after dedicating his life and career to developing and improving lean manufacturing principles across the manufacturing industry. Norman Bodek…

Read MoreWhat are the new trends in lean manufacturing?

Lean manufacturing continually strives for improvement. Naturally, it also sees room for innovation, growth, and the opportunity to further reduce waste in business operations as the manufacturing industry evolves. This year, some key trends are emerging in lean that, as C Tek shows, can help your business improve its efficiency and in turn keep its…

Read MoreHow to describe lean manufacturing to beginners

Lean manufacturing encompasses a variety of principles, but ultimately, the goal is to promote profit. Lean manufacturing is a method utilized by companies to continually reduce waste and improve their products. By incorporating lean principles and practices into their business philosophies, companies successfully save money, reduce waste, and improve their customer service. C Tek explains…

Read MoreWhat is the difference between green belt and black belt in six sigma?

There are different levels of proficiency that one can achieve to become certified in Six Sigma. These levels of certification demonstrate a mastery in the principles embodied by Six Sigma. Certification levels range from the White Belt to the Black Belt. They differ primarily in the level of knowledge obtained. As the experts at C…

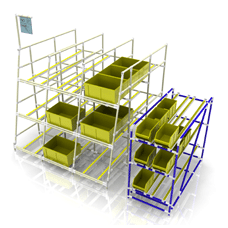

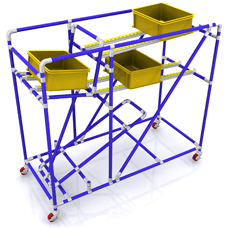

Read MoreHow does a cellular layout contribute to lean production?

Companies continually seek ways to become more efficient and productive. Lean production helps make that happen. Lean production continually strives for improved efficiency and customer satisfaction. One component of lean production is cellular layout. Cellular layout refers to the way specific departments within a company are organized. An efficient layout plan, as C Tek explains,…

Read MoreHow will big data affect lean manufacturing?

Big data and artificial intelligence (AI) have been increasingly important in many industries. With the ability to streamline production processes and maximize efficiency, they also have the potential to help lean manufacturing in many ways. In the coming years, big data is expected to play such a critical role in manufacturing that up to 47…

Read MoreDifference between JIT, Lean and TPS

There are several types of guiding principles and philosophies in manufacturing. Sometimes, it can be hard to keep them straight. If you’ve heard terms such as “lean,” “Just in Time,” or even “Toyota Production System” applied to manufacturing processes, but you’re not sure what makes one different from the other, the experts are C Tek…

Read More