Starter Kits Introduce You to the World of Pipe & Connector Kaizen

By Mike Kennedy

The use of pipe & connector systems within your manufacturing, assembly or distribution operation significantly changes the way you look at your work floor. Normally, catalogs are called upon to search at length for various structures used to make improvements and changes to your processes. This involves endlessly searching for structures page-by-page that only partially do the job you need them to do. You are bound by standard sizes and designs that might not be most beneficial to your floor space, floor layouts or operator needs and wants.

Wouldn’t it be great if your team could brain-storm exactly what structure(s) are required for the improvement, their size, and design? Quickly sketching it on a whiteboard and then moving out to the floor and building the structure together and getting it operational on the work floor the same day. Compare that to finding and ordering something from a catalog, waiting a week or more for it to get delivered, then having to assemble before moving to your work floor. And then discovering it does not do exactly what you want, but you must live with it. Why?

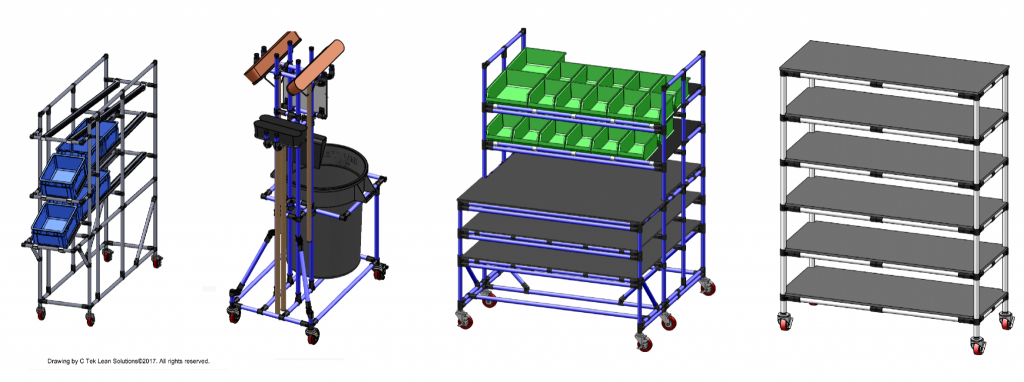

A Starter Kit supplied by C TEK is an economical and essential tool to familiarize yourself and your company with Kaizen, or Continuous Improvement by using modular pipe & connector systems to make immediate positive change in your processes. These changes could come from designing more efficient and ergonomic workstations. These changes could come from designing a line-side supermarket flow rack, exactly around your tote/bin sizes to lessen the travel time between work cell replenishment, while saving floor space. You can build anything you can imagine, most of the time for less cost and in less time than ordering from a catalog. Then you can make changes to continually evolve the structures based on operator input.

Modular Systems by C TEK will instill pride of ownership to everyone involved in the creation of the structures. It will bring your teams together and always keep them thinking about ways to make improvements leading to shortened lead times, increased picking and assembly accuracy, and more ergonomic conditions. And when your processes change and your current structures are not required anymore, they can be disassembled, and all the parts can be recycled and reused again in new structures.

C TEK Lean Solutions is your Lean Manufacturing partner. In addition to introducing your team to Kaizen utilizing pipe & connector systems, we can also provide you a free day of on-site training soon after your Starter Kit arrives. During this time, we will work start to finish with your team by brainstorming and designing the structure. Then building and deploying it into operation on your floor. You will learn all the most efficient ways to build with our modular system and learn what all the various connectors can do for you. After a day of Starter Kit training, you will be off to the races, building what you need, exactly the way you need it, and when you need it.