Free Up Valuable Floor Space and Increase Production Using Modular Pipe & Connector Systems

by Mike Kennedy

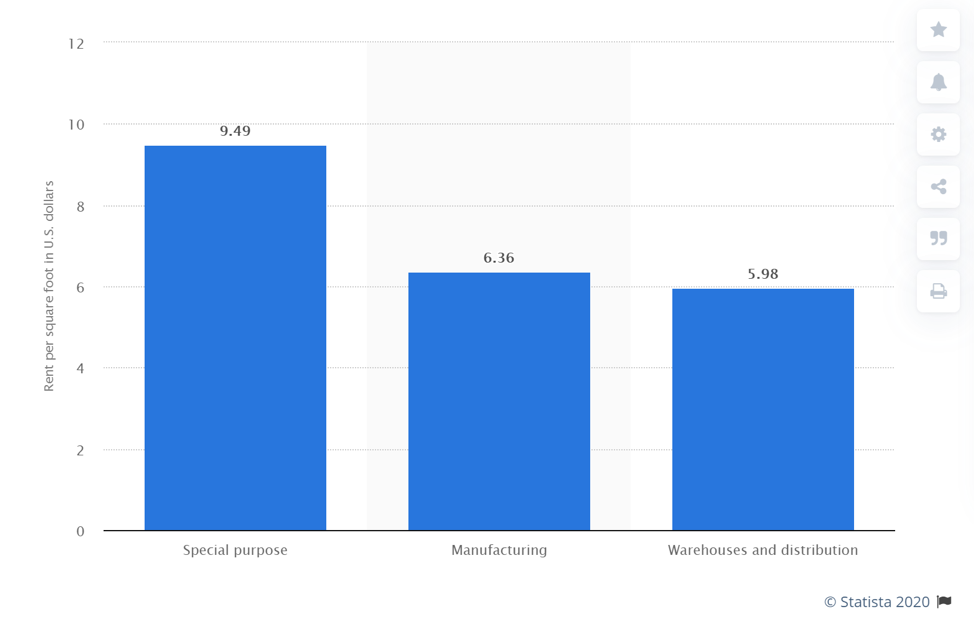

What is your cost per square foot in your current facility?

Are you running out of floor space for your manufacturing, assembly, or distribution operation? Are you considering moving into a larger facility with more floor space? What are the costs associated with such a move in today’s economic environment? Is there another option to consider for increasing your production within the space you currently occupy? The answer is a resounding YES!

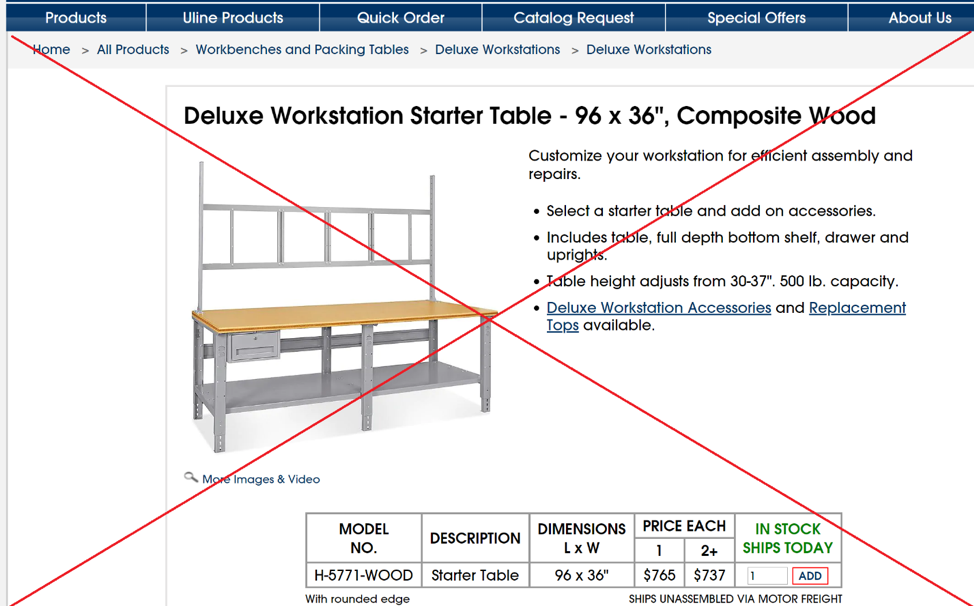

Efficiently utilizing one’s space is a never-ending balancing act while trying to grow your business. How do you produce more but in less space? One option is taking a detailed look at your entire work floor and seeing if there are ways to reduce the amount of space (read that, WASTE) required to get the job done TODAY. Many of today’s work floors are covered end-to-end with a variety of material handling structures, ranging from catalog purchased workbenches, carts and racks to structures made in-house with wood or steel. Many of these types of structures come in standard lengths of 4’, 5’ or 6’ or more. What if you only need a 36” workstation but are forced to buy 60” workstations because that is the only size they are available? Now multiply that additional 24” to all the workstations on your floor. Can you start seeing that by utilizing standard-sized structures (whether that is workstations, racks, carts, shelving, etc.) you are eating up valuable floor space?

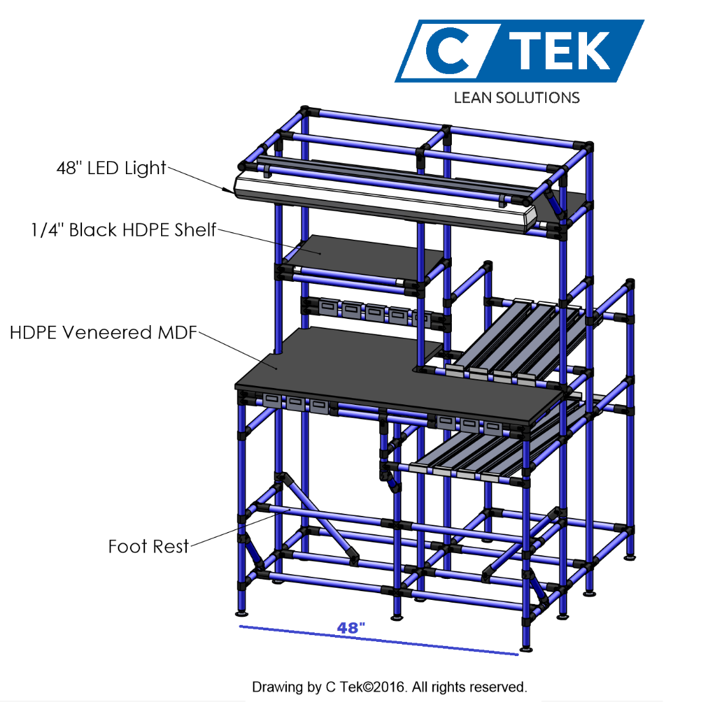

Look at ways you can shrink up your work cells by building your own workstations (and associated feeder racks, transportation carts, etc.) and assembly cells from a modular pipe & connector system from C TEK Lean Solutions. Discuss with your floor operators how much space they require to do their job. Look at ways to reduce the clutter on work surfaces by designing overhead shelves into your next stations. Downsize your workstations to just the length and depth required by the operator by locating everything they need (tools, parts, computers) up and off (or under) the useable work surface. Many times, doing this will reduce the space needed to do their tasks and ultimately will open additional floor space to add more assembly lines and help increase production, all while utilizing the space you currently are in. At the same time, you will likely also see efficiencies like producing more within a shorter amount of time. It is a win-win proposition!

Consider the comfort of your operators and how it effects their output, either raising or lowering the work surface to an optimum and ergonomic height for your workers or consider adding a footrest. C TEK offers height adjustability options so your workstations and be lowered or raised for various workers using the same station. Computer flat panel monitor mounts can get pc screens off the main worksurface and place them overhead freeing up more workspace. Keyboards can be placed on trays that slide in and out from under the worksurface. These are all things you can do to free up the minimum necessary space for your workers to do the job and do it in less space.

Contact C TEK Lean Solutions to learn how a modular pipe & connector system can help you free up valuable floor space by creating “right sized” and designed workstations, work cells and complementing racks, shelves, and carts. Produce more in less space and in less time. C TEK Lean Solutions can show you how to do it.