101 Essentials on Building with Pipe and Connector

You have probably seen pipe and connector structures used in different manufacturing environments. You may have even built projects with the materials around the house. These versatile construction components, however, can be used beyond simple projects, and help you improve your company’s production line.

Any lean manufacturing or management program relies upon making instant changes to problem solve. Using the Japanese kaizen method of walking the floor and immediately addressing problems that arise, lets you quickly address things before they create a bottleneck.

The versatility of steel pipe and connectors lets you quickly join components to build an array of lean structures to enhance the productivity and safety of your facility. Armed with an Allen wrench, you can swiftly assemble ergonomic workstations, tables, carts, sign boards, flow racks, and more. You simply need enough pipe and a selection of two-, three-, four-, and five-way connectors.

Key Benefits

The versatility of the pipe and connector system allows you to customize virtually every aspect of your manufacturing work flow. These parts work together seamlessly so you can add to a kitting/picking cart, expand with shelving, create ergonomic workstations and design flow racks that work for your specific needs. Key benefits of structures made of pipe and connectors include the following:

• Bolt together for easy with quick assembly.

• Immediately modify and evolve structures as needs change.

• Reuse/recycle pipes and connectors from disassembled structures.

Design Ideas

C Tek Lean Solutions offers on-site engineering and assembly support associates, so if you don’t feel comfortable building something yourself, you have readily available assistance. They can also offer pipe pre-cutting, if you just need a little help getting started on a bigger job. Here are a few structures ideas to create safe and efficient workflows:

1. Create a safety fence to cordon off an area. This quick assembly method lets you physically limit access and signal where employees should avoid.

2. Create a walkway that directs traffic by constructing railings that limits access on both sides.

3. Improve the ergonomic nature of each employee workstation by instantly addressing needs for rack storage, adjusting height for comfortable reach, and designing with individual employee safety in mind.

4. Provide a bench for workers to rest on or stand on to reach needed items.

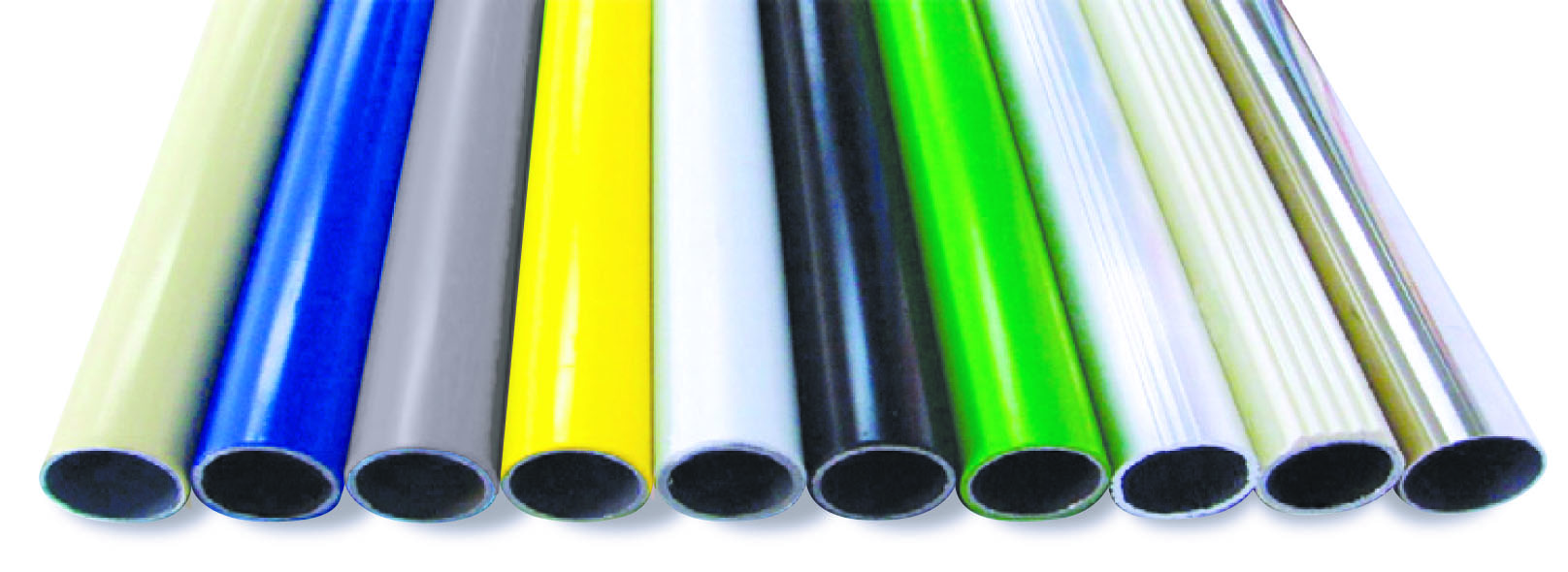

5. Use colored pipe and tube to match OSHA requirements to denote safety areas.

Lean Tenets

Too often people get caught up on one portion of the lean definition. They work on maximizing customer value by focusing on product development or they work on eliminating waste by altering processes. But lean manufacturing does both – maximizes customer value by minimizing waste. That means you create a better product using fewer resources while providing better customer service.

The use of pipe and connector simplifies processes, so they require less capital, human effort, space, and time to produce. You can easily and quickly craft solutions with a few tools and your imagination.

When implementing lean methods, people easily get used to focusing on improving manufacturing methods, but this method also improves office environments and product presentation. Merge your creativity with this business management system to create new, streamlined ways in your organization.