6 Custom Carts to Increase Floor Productivity

The cart, utilized on almost all work floors, is one of the keys to enhanced floor productivity. While many still utilized multiple uniform structures, carts provide optimum benefit through customization, providing invaluable benefits.

Benefits of Carts

Using carts to move products achieves five important items in one device:

1. Ergonomics

2. Safety

3. Space Savings

4. Travel Flexibility

5. Versatility

Carts provide the answer to many production issues. If you walk the floor regularly using the kaizen technique, you can quickly create a better lean manufacturing environment by changing small problems you spot to alleviate bottlenecks, improve employee safety, comfort, and productivity. Using pipe and connector, you can create a cart system to improve work flow, reduce injuries, and increase productivity so workers can focus on high value activities.

Types of Carts

Carts let you move large or small items easily throughout the work floor. This lets you increase material productivity and enhance safety by eliminating or reducing an employee’s need to bend, lift, or twist – the three main causes of work place injuries.

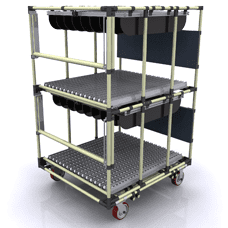

Carts come in various sizes and designs to suit any production floor layout and ergonomic need. You can create custom carts from any type by adding items like pipe and connector to enhance interface with any workstation. Easily move items from carts to a rack with customization. Basic types of carts include:

1. 5S Carts: Workplace organization carts creating a standardized work area through the five S’s of sorting, setting, shine, standardization, and sustained improvement.

2. Bump-N-Go Carts: This bump cart system makes it easy to keep parts at the operator and does not require him to move (or lift totes). Great for reloading line side racking, work areas, and storage racks. No automation or air needed.

3. Flow Carts: Move materials through the industrial or manufacturing process.

4. Tool Carts: Provide easily-accessible, rolling storage for tools, plus work surface.

5. Transport Carts: Move items like mail, food trays, or dry wall,

6. Tug-Trains: Also known as tugger carts, these carts replace single load deliveries by forklifts with a sequenced train of items plus provide a greener solution.

While manual material movement normally requires coordination, precision, and strength, carts enable those of all strengths and sizes to easily move items safely. Employees can efficiently move materials between loading docks, rack systems, storage areas, and from one workstation to another. That lets you reduce production time, eliminate or reduce parts collection downtime, reclaim floor space and free up capital by using low-cost, highly scalable and customizable methods.

Work Floor Implementation

Implementing multiple types of carts lets you improve flow without huge expense. Rather than an expensive motorized conveyor system, you enable transport of materials and finished product manually while maintaining efficiency. A system of carts lets you immediately implement cart service to a specific workstation without restructuring or retrofitting equipment. Using tube or pipe and connector, you can customize a cart to each workstation’s needs.

Contact C Tek Lean Solutions to learn how to implement carts in your production space to save money and increase production. C Tek can help you implement lean manufacturing methods that better serve you and your customers.