4 Benefits of an On-Site Visit

Getting Ready for Company

Implementing “lean” is a journey. Many employees will be unsure how this process will impact their activities — open and candid conversations will uncover opportunities on how lean can improve their efficiency and job satisfaction. We find many of our partners prefer us to assist in this “discovery phase”. During a brief conversation (often via WebEx or Skype), we can get to know your company and determine your personal lean goals. Practicing lean solutions means being cost-effective for your company, and many can start that voyage without the expenditure of a visit.

For some companies, the right start to go lean is an on-site visit, meeting in person with one of our designers or engineers to specifically assist you with the next few steps. If you are still curious as to the advantages of an on-site visit, and whether your company truly needs one, check out our list below of the 4 reasons to schedule a visit today.

1. Our Engineers and Designers Bring Years of Experience to Your Manufacturing Floor

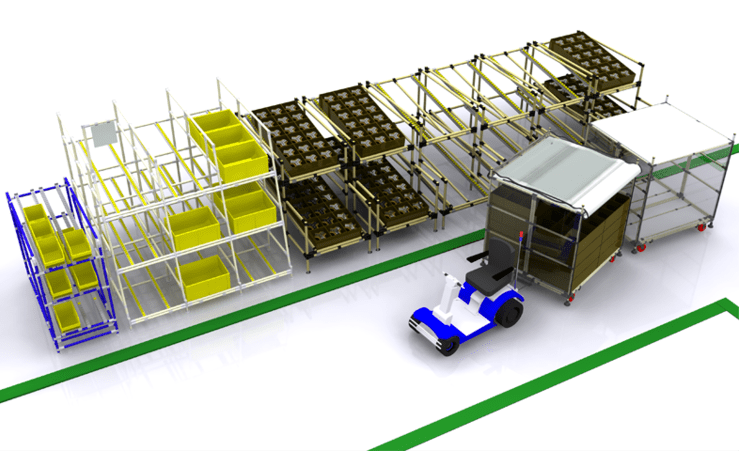

Going lean is an incredible opportunity for companies to save, which is why it is important that all applications are designed specifically for your workspace. Our team member will ask to walk your space on their visit and make note of the initial setup of your floor. They will also take the time to discuss its current function with you, and identify what works in your layout and what can be modified by our methods. This visit allows for an out-of-the-box approach to solutions that your company might have not seen before, and assist you in how to proceed.

2. Discover How You Can Save Space

Different spaces require different lean solutions. Some floors function in ways that would never work at other locations, and vice versa. These differences all boil down to the utilization of space. There are companies, for example, with the room to have a far-reaching layout, while others must be cognizant of how each cell is used. A Lean Representative will not just look at your space but also look at the functionality of that space. Is the design of your current layout ergonomic? Is it important to limit your team member’s footprint? Our representative will determine how crucial these questions are to your lean success.

3. Learn What Applications Can Make the Largest Immediate Impact

The correct applications can create a world of difference for your team once you become aware of the capabilities of each structure. Our representative will walk you through what applications would work best in your space and how they can eliminate additional structures or restructure your use of manpower.

4. Get An Outsider’s Opinion

Our team brings over a hundred years of lean expertise to your shop floor. This provides your team with the industry expertise that can drive the design and implementation of lean structures. We believe that it is important to get the full picture of the floor from all departments and players to move forward with implementing lean solutions.

Most benefits of an on-site visit can be implemented through a phone call or teleconference / videoconference. We look forward to assisting you to reduce waste in your operations and are excited to partner with you in achieving your lean goals.